State of the art

Chocolate Cooling

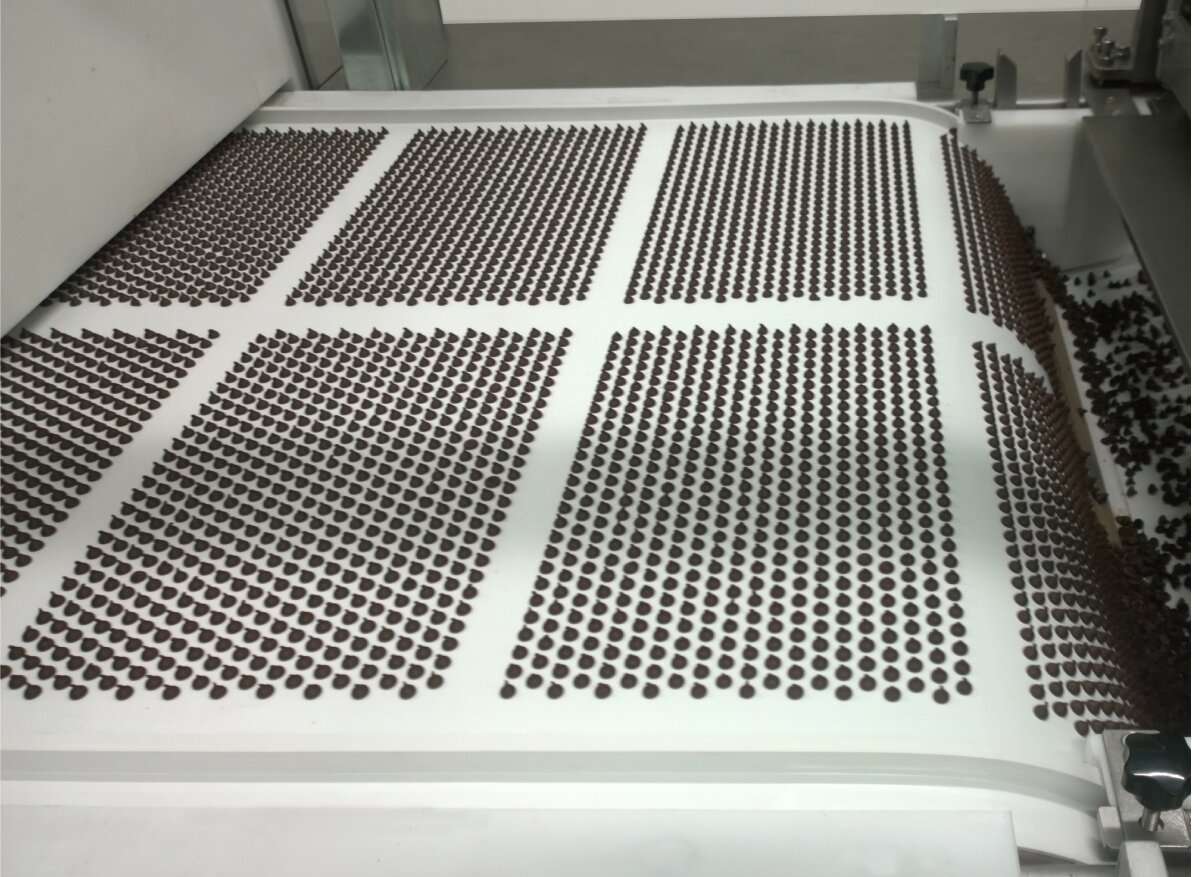

Delver cooling tunnels just represent the state of the art in chocolate articles cooling, either for layered, belt deposited or moulded products, for crunchy dark chocolate to delicate praline

and truffle masses.

Double cooling action

Belt Tunnels

Outstanding efficiency pairs with the most accurate control to grant each article is cooled exactly to the mass crystallization point required by each step of the production process from subsequent layering, to cutting and finally detaching the articles from the conveyor.

A double cooling action, consisting of direct ventilation of top of the products and cooling plates in contact with the article conveyor bottom, is carried out by proportionally modulating the cooling agent flow to reach absolute accuracy in temperature control and stability in time.

Stainless steel hinged covers with assisted opening, careful, hygienic design of the complete structure and advanced supervising software complete the oustanding features of these new generation cooling tunnels.

Adjustable ventilation

Mould Tunnels

Either horizontal or vertical, designed to fit perfectly the requirements of any chocolate moulded article, Delver cooling tunnels offer high efficiency and perfect accuracy in temperature control granting homogeneous, adjustable ventilation of the entire mould surface.

This comes together with a stainless frame designed to grant complete, comfortable accessibility and wide see through secions to easily follow the entire mould path in the cooling chamber.

Moreover the different mould conveying systems available are designed to grant absolute reliability integrating the tunnels in fully or semi-automatic production lines.

Get in

Touch

Get in touch with our team to learn more about Delver’s range of custom machines, production solutions and services.